An air compressor is an essential tool for any DIY enthusiast.

They can be used for numerous applications, most commonly to power pneumatic tools and give you complete power over nailing, spraying, hammering and sanding at a fraction of the time it would take with manual tools.

They can also be used for car repair projects, inflating tyres and even creating your own home-made snow machines.

You can attach numerous tools to your air compressor such as angle disc grinders, die grinders, grease guns, impact wrenches and sandblasters.

As much as we love our power tools, it is becoming more apparent that we need to focus on reducing carbon emissions and cutting our carbon footprint. Small changes in our own home is a great start to help save our planet and try to decrease climate change.

Whether you are looking to invest in your first air compressor or update an older model, Direct Air has created a helpful guide on why you should choose an oil-free air compressor. You can see their full range at here.

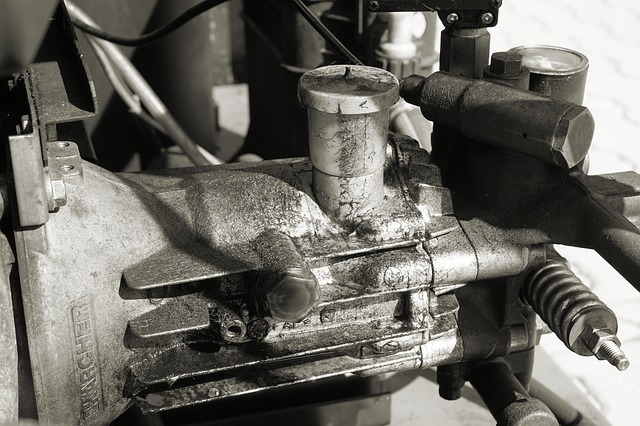

All air compressors require lubrication to safely and efficiently draw in air through the cylinder, typically with a piston movement, but this can vary.

An oil-based air compressor does have its benefits, these machines are very robust and will have a longer lifespan for more demanding tasks. However, if you are using an air compressor for do-it-yourself tasks, there is little need to purchase such a machine.

An oil-free air compressor achieves its lubrication with the addition of a non-stick coating, typically Teflon. As these machines do not require added elements to hold oil, they are far lighter and smaller than their counterparts, making them perfect for your home workshop as they are easier to move and store when not in use. They are also usually more affordable.

They can also operate in more than one orientation, as they eliminate the worry of ensuring oil is upright and correctly flowing so you can position them wherever you please. You can also operate them at any temperature, perfect for a cold garage, as oil becomes more viscous in cooler temperatures and can cause problems when attempting to start the motor.

The benefits of an oil-free air compressor are huge compared to the oil-based counterpart. However, you will not only be saving the planet but also reduce your own running costs of your new air compressor.

Firstly, you will reserve natural resources by not using oil but also eliminate all costs to collect and dispose of oil-laden condensate. Oil-free air compressors are less wasteful as you are eradicating the need to replace the air/oil separator elements and filtration elements required to get rid of oil aerosols which can wear down quickly. Therefore, you will not be using and throwing away broken elements or have to pay for new ones.

As an oil-free air compressor provides the purest form of air, you will reduce harmful emissions into the atmosphere whilst not having to worry about any contamination or spillage, saving your floors, clothes and any items that could become contaminated during your projects.

These machines are also safer than their oil-based counterparts, an essential factor to consider when working anywhere, but especially in your own home. As there is no oil, you will not be at risk from the potential of compressed air pipelines fires cause by oil.

Oil-free air compressors also simply reduce your energy bills as they require far less electricity to be powered, in turn, reducing your impact on the environment. Oil-free machines have no need for an increased force that is required in oil-based air compressors when a unit sees filtration drop the downstream pressure. An oil-free air compressor can unload at an average of two seconds of the command and will only use about 18% of their full load horsepower when doing so.

There is one downside that is often attributed to oil-free air compressors and that is the noise they make. Typically, an oil-free air compressor generates more noise than their counterparts and this can become an annoyance to the user and those around them.

However, there is a solution. Low-noise air compressors are available which reduce the noise level to around 40dB. To put this into perspective, 60dB is considered the lowest, safe level for an air compressor and anything above 80dB can cause lasting damage to your hearing.

Low-noise air compressors achieve this with the addition of an acoustic cylinder to store the noise. We do recommend that with all power tools, even low-noise ones, that protective gear is worn to protect your hearing from long-exposure and ensure there are no long-term effects as a result of your air compressor.

If you were thinking of purchasing a new air compressor, or perhaps you weren’t but have now been swayed, you should now have a full understanding of the benefits of an oil-free machine and why they are (almost always) the best choice for your home workshop.