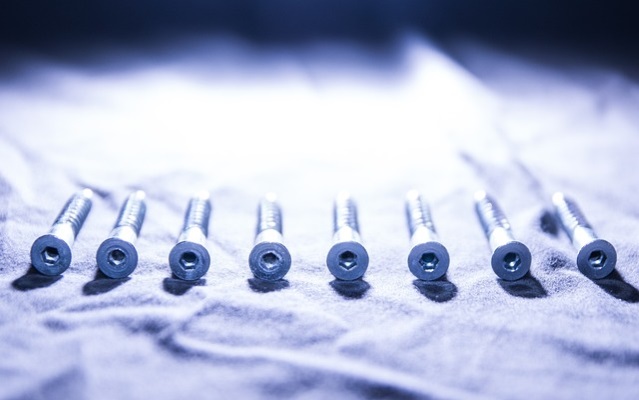

If you’ve done any DIY, I’m sure you’ll have wondered about the types of socket screws…

Let’s take a look at the two main types and when to use them

Fasteners are the most crucial part of many home and business projects. Without them, things would fall apart – quite literally. But there are several different types of fasteners, and you might not know which one is best to use for which scenario.

There is one type of fastener known as a socket screw. Before you know whether or not to use them, it helps to know the different types and what they bring to your next project.

Look for the hex head

What are Socket Screws?

These screws go by a few different names but socket screws are for applications where a nut and bolt just won’t do. The most easily identifiable feature of socket screws is the hex head, which can be adapted to suit a countersink, button, or fillister head, among others.

While nuts and bolts may be preferable for heavy-duty applications, there are times when the space does not allow for it. If you don’t have the proper space to tighten a nut and bolt, then the socket screw is the next best thing and will do a great job.

The Two Main Types of Socket Screws

While there are several subsets of the socket screw, there are really two main types that you’ll see for your everyday projects. Those would be the button head socket screw and the countersunk socket screw. Let’s get a little further into each of them.

Choose wisely

Button Head Socket Screw

This is the most common type of socket screw and it is easy to identify because of the round or dome head that identifies them. Of course, you can also look for the hex head as well. Button head socket screws are manufactured with a slightly rounded, smooth dome for a head. They tend to be a bit more bulbous and larger than your average cap screw.

Because of its shape, the button head socket screw can typically handle larger gauges of hex driver, which means that greater torque can be achieved in the process. Smaller hex button screws, however, should not be tightened with quite as much force.

Countersunk Socket Screws

The other common type of socket screw is the countersunk hex. You might see these called the flat head socket or simply flat socket screws. These are generally used in applications where the screw needs to sit flush or just below the surface of the material in question.

These screws generally have a roughly 82-degree angle sloping shoulder design. The purpose of this is to allow the screw to make its way just below the surface when applying them to pre-drilled holes. These come in a huge array of widths and lengths, giving them great versatility.

What are the Main Advantages of Socket Screws?

The single most important benefit of using socket screws is the improved clamping force and torque that they provide. Compared to regular screws, socket screws deliver a substantial amount of force that applies to more heavy-duty applications. That improved torque is crucial for holding workpieces together that normal screws could not accommodate.

Depending on what material type you choose, you may be able to keep hardware costs down as well. Most jobs hinge on the budget and being able to save on hardware can wind up making a difference elsewhere.

Finally, there is the weight of these screws to consider. If you are working on a project where weight plays a role, socket screws are going to be your preferred option. They have a slightly lower weight than other fasteners, making them more ideal where a difference of even a few ounces can wind up making a big impact on the project.

If you’re looking for a way to fasten the screws, check out the GTech cordless drill, which you can also use as an electric screwdriver.